Shape Your HMI Data Model

So your team already has a rough idea or even better: wireframes or design mockups of what your HMI should look like. But the PLC development hasn't started yet? Let's have a look at how to set up and structure your HMI data to be able to start building the HMI without having access to the actual PLC.

- Decide how to structure

Let's start by working out what basic data you actually need in your HMI and how to structure it. Of course, you can always change this structure later, but having a good baseline will help you a lot later on.

If you're building a project with a cross-functional team, this is usually a team process. Based on wireframes, you will create a first proposal that you will shape with your team.

- Create the structure

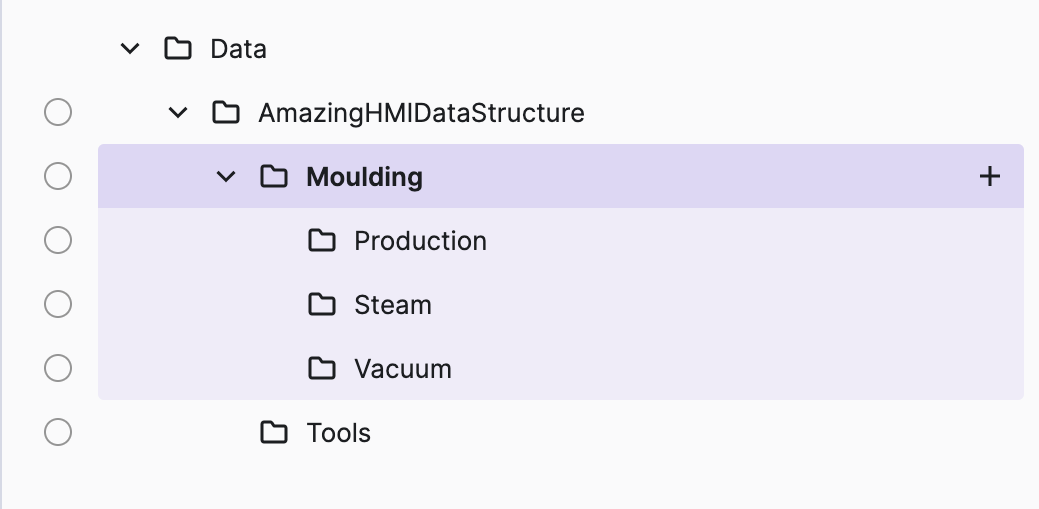

In this example, the product team wanted to organize the data according to how it's used in the HMI. But feel free to create any structure that suits your needs.

- Open your project in the Project Editor and switch to the Data View.

- Start by creating directories using the HMI Data Explorer.

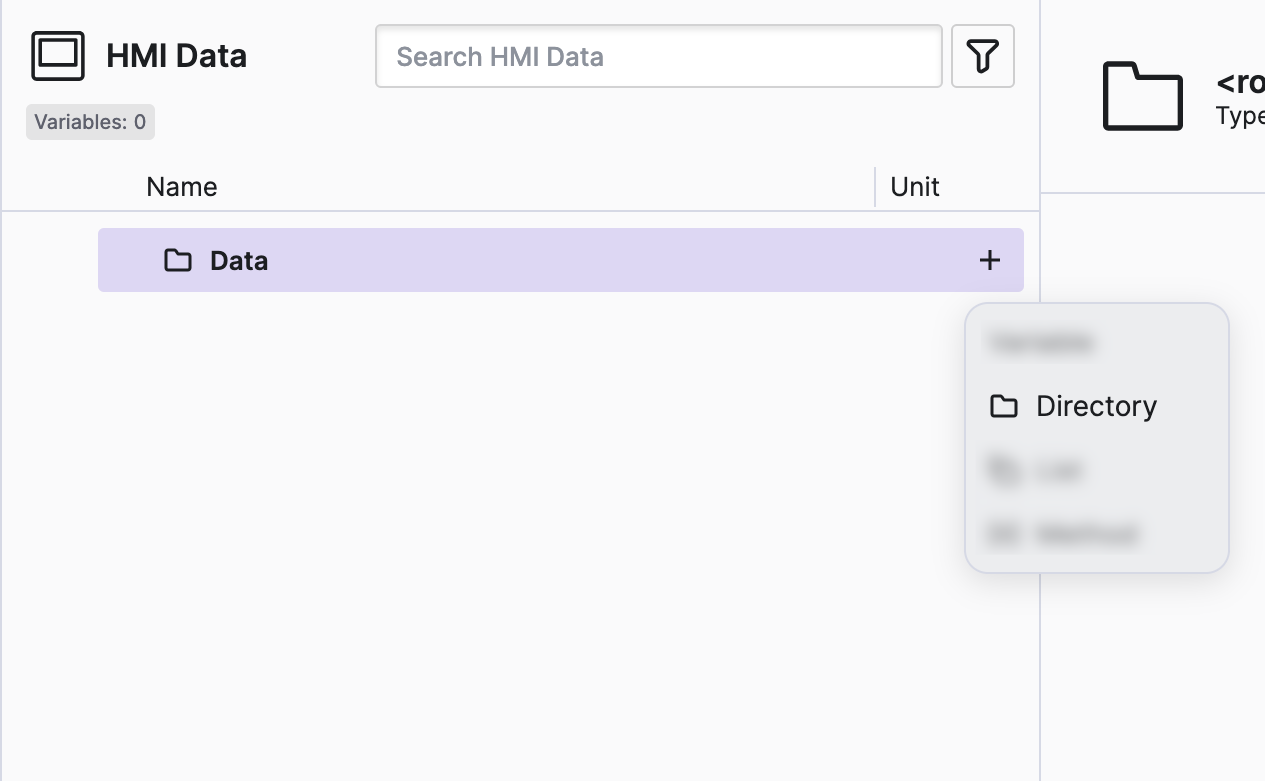

- Click the

+button next to theDatadirectory and selectDirectory.

Your result data structure should look like this:

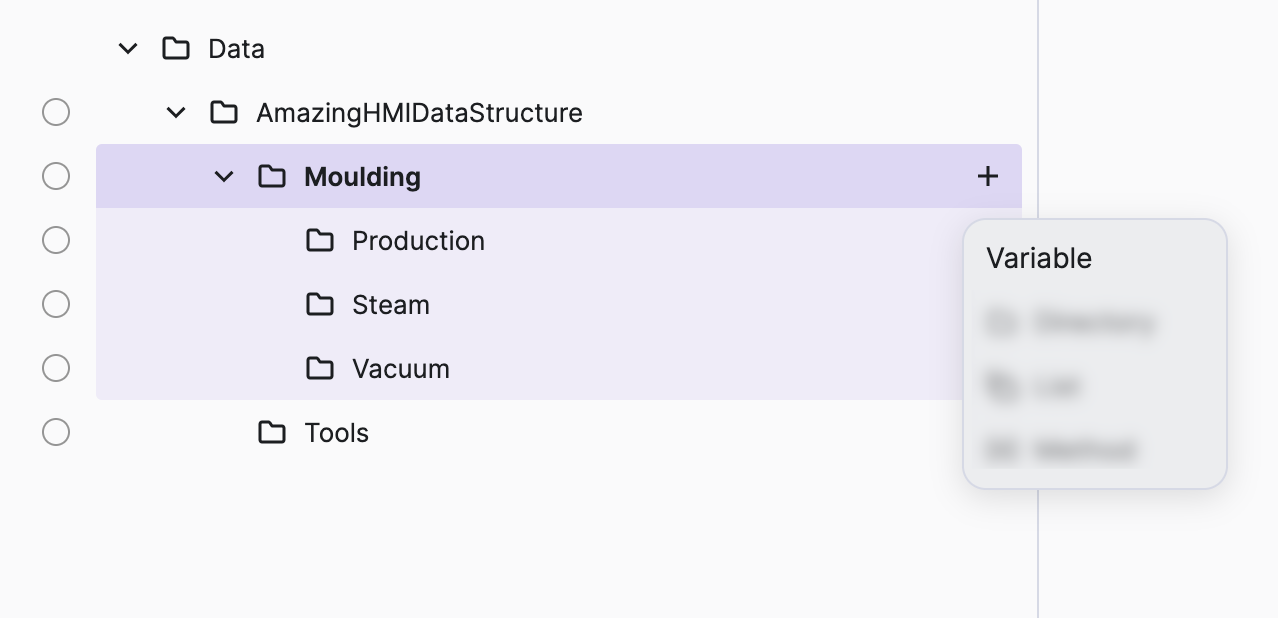

- Add data

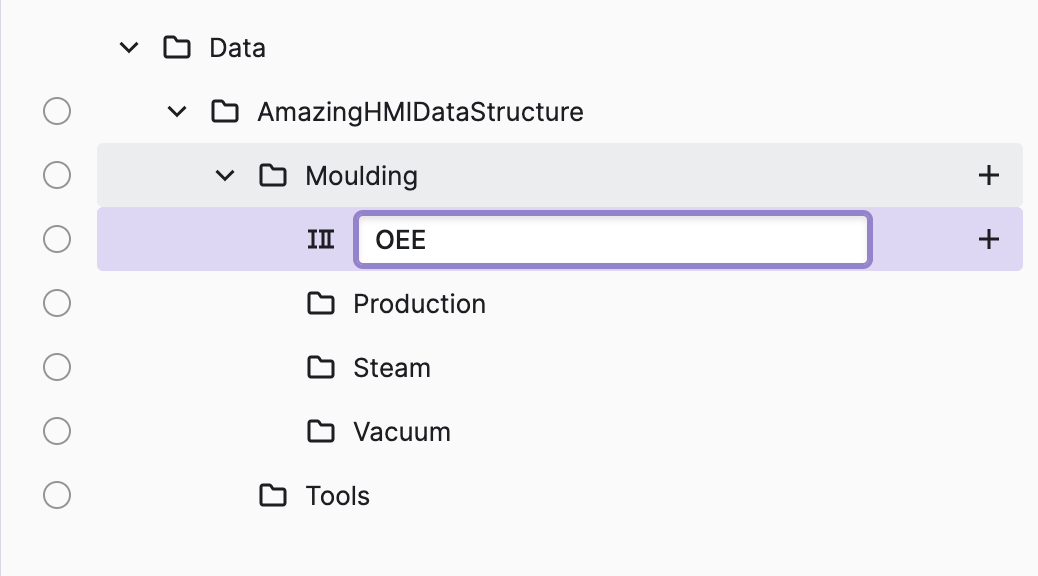

- Name your data

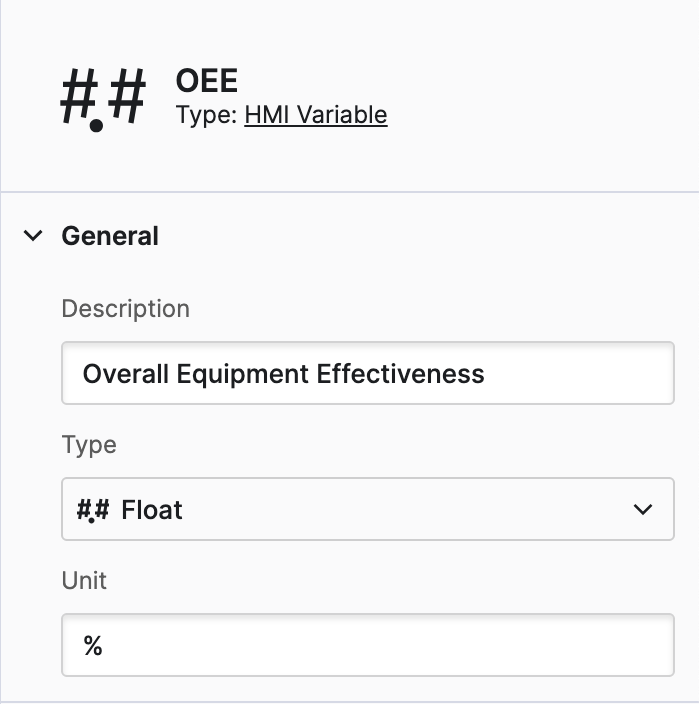

Once you've created a variable, you can set its name right away if you want to. You can always change it later if you feel the need. For this example choose OEE as the name.

- Augment with metadata

One of the strengths of HMI Data in HELIO is its ability to integrate additional information, providing HELIO with the capacity to present more comprehensive input and output elements for more effective input and control of this variable.

- Choose

Floatas the type of this variable. - Add a description to let other team members know the details of this data.

There are a lot more properties you can set for each of your HMI data variables. See Common Properties to learn more.

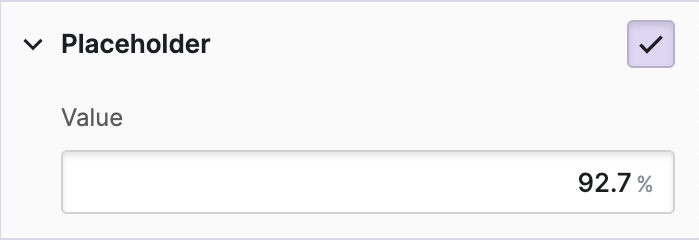

- Define placeholders

You've created an HMI data structure! You are now ready to start creating and editing your HMI. Once that's done, we'll move on to the next step: connecting the HMI data to your PLC.